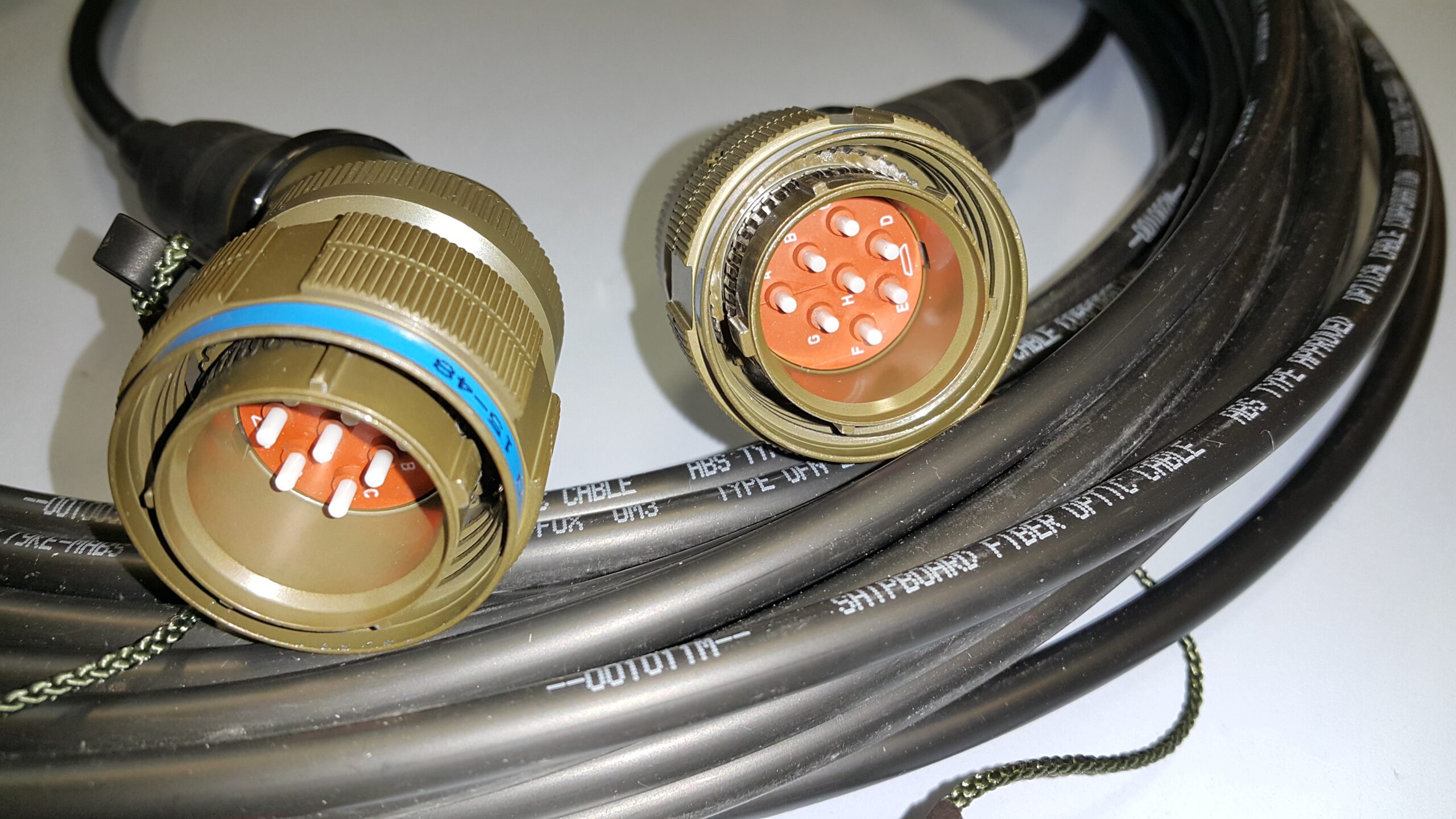

The same durable and flexible cables described for deployable tactical jumpers with hermaphroditic connectors, which can be used in deserts, in marshes, frozen lakes or mountain streams, can be also equipped with environmentally resistant non-hermaphroditic connectors (e.g. D38999-III with optical fibre contacts M29504/4 & /5 or ARINC 801).

Such solutions also have their own advantages not available to hermaphroditic connectors, the best example being the „ratchet” in mechanical interface of D38999 connectors – its design causes automatic self-locking of the connector as a result of vibration of the object, on which they are fitted.

Similarly, connector with locks allowing quick mating and un-mating (e.g. „push-pull” or „breakaway” type) are much easier (therefore cheaper and smaller) for arrangement in typical connectors.

Non-hermaphroditic connectors will normally ensure higher contact packing density,, so smaller dimensions and weight than connectors described for deployable tactical jumpers with hermaphroditic connectors.

Deployable tactical jumpers with regular connectors can prove especially useful in the case of modernization of military equipment – everywhere where the use of optical fibres instead of electrical connectors is required. In the same connector housing, it is possible to install appropriate optical fibre contacts instead of electrical contacts without the need to modify the unit’s housing.

In this product line we offer both physical contact connectors and expanded beam connectors.

A particular example of application of such lines are deployable tactical jumpers used for remote control of robots (e.g. mine robots), most often equipped with single-channel connectors for extreme operating conditions (e.g. MFM simplex). Design of such tactical jumpers requires special cables – with small diameters and high wear strength. Small diameter is achieved by using a cable with single fibre – optical fibres allow two-way transmission of data via one fibre, additionally, the single fibre enables parallel (simultaneous) transmission of many data channels (WDM technology). This type of solutions requires the use of fibre optic rotary joints (FORJ) – as only these ensure continuous, uninterrupted data transmission with rotating reel rolling/unrolling optical fibre following the moving robot.

Design: Proformat