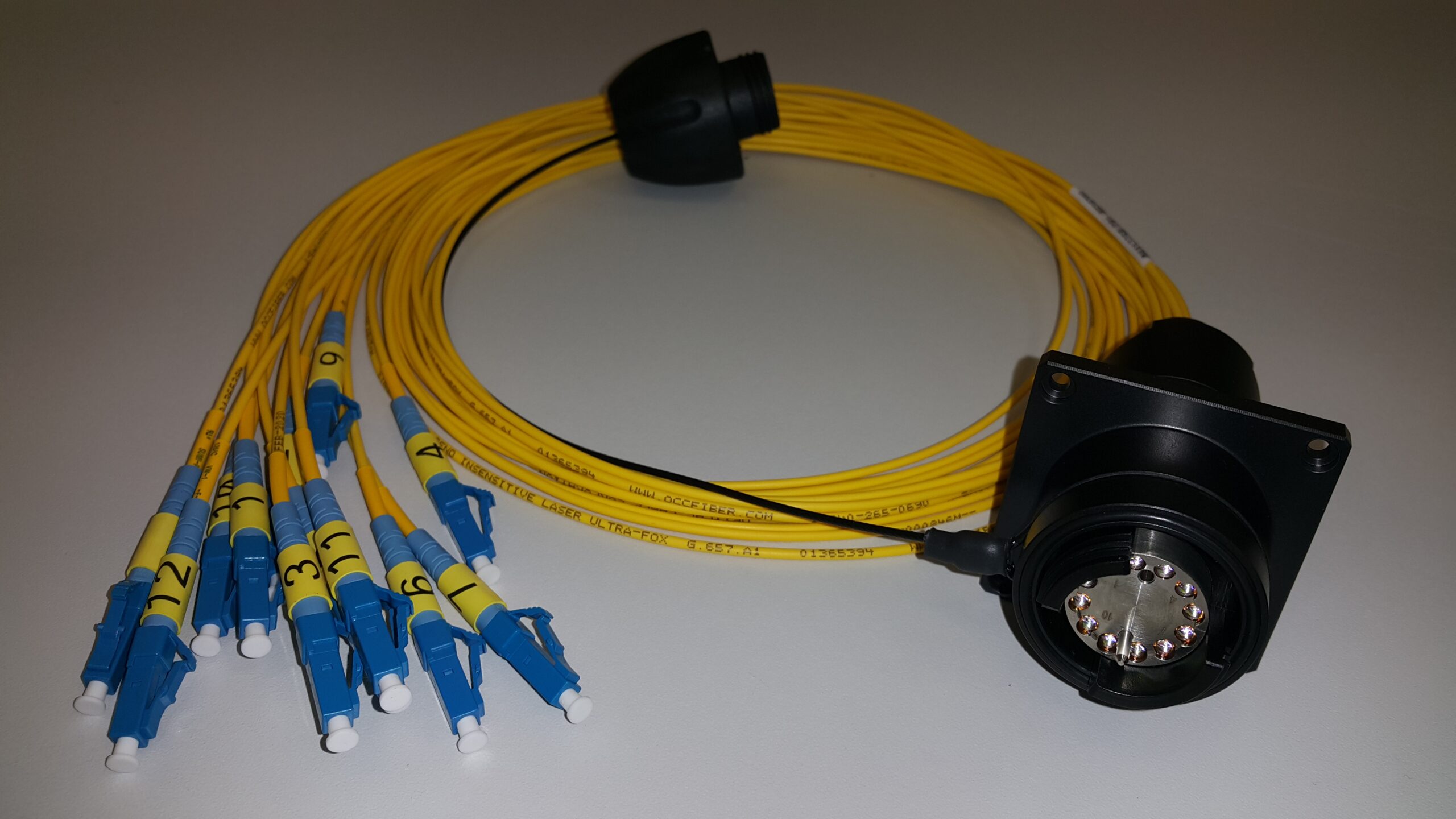

Expanded beam bulkhead assemblies are optical fibre harnesses consisting of 3 elements: expanded beam bulkhead connectors with high environmental resistance (e.g. CTOS), sections of fiber optic cable and standard optical fiber connectors (e.g. LC).

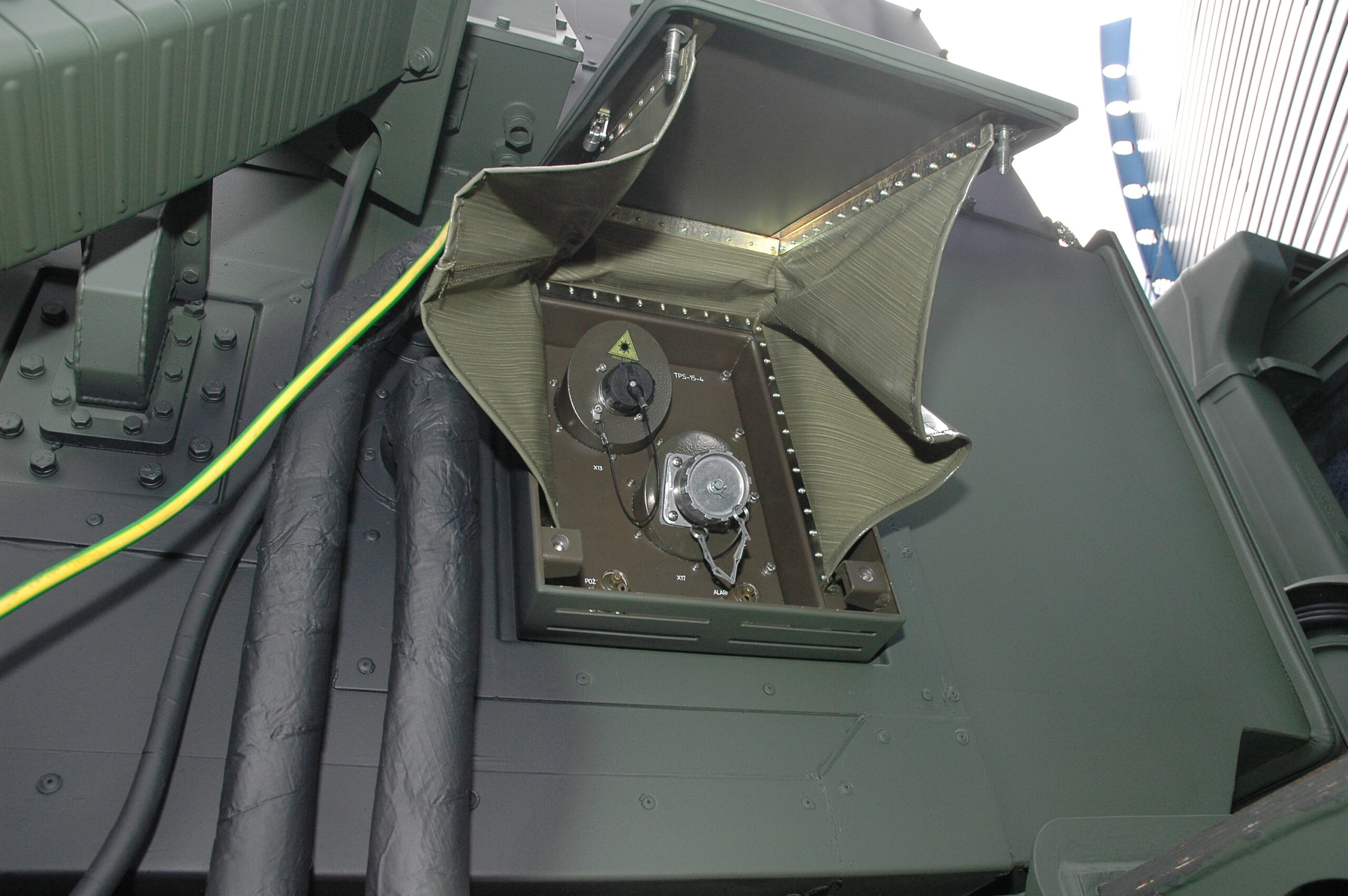

These solutions are mounted on the case of a device or vehicle and they allow connection of deployable tactical jumpers to systems located inside. The expanded beam bulkhead connector provides an environmental barrier protecting equipment and people located inside from adverse effects of external environment. In addition, such solution has a very beneficial impact also on electromagnetic compatibility.

Standard optical fibre connectors located on the other side of the harness (most often single- or double-channel: simplex or duplex) can be connected to active devices (e.g. SFP modules) installed inside the equipment or vehicle. In cases where instead of a standard connector an non-typical connector is required, Radiotechnika Marketing is able to provide any solution customized to needs of the customer.

The main advantage of expanded beam bulkhead assemblies is increased resistance of expanded beam connectors to dirt and dust – thanks to widening of the light beam diameter from 9μm (SM fibres) or 50μm (MM harnesses) to approx. 0.5-0.8 mm, expanded beam connectors are characterized by lower susceptibility to contamination. The expanded beam connectors have an air slot between lenses which ensures a key advantage over physical contact connectors. Thanks to this, when used under difficult environmental conditions expanded beam connectors are “indestructible”– if two dirty expanded beam connectors are connected, in the worst case the signal will be attenuated, but the connectors will not get damaged – they will start to work properly after cleaning. Contrary to physical contact connectors, which, if connected while dirty, will almost always end with irreversible damage (total or degradation of parameters).

Design: Proformat